biogas

I believe everyone will definitely not be unfamiliar

Combustible gases produced by fermentation of poultry and livestock manure

It's called biogas

Our Hailong Village is most famous for biogas

China Biogas Expo Park

The First Village of China's Biogas Energy Revolution

It refers to Hailong Village

What exactly is biogas?

Why should we vigorously develop biogas?

The editor has compiled relevant materials for everyone

Let's take a look together

What is biogas??

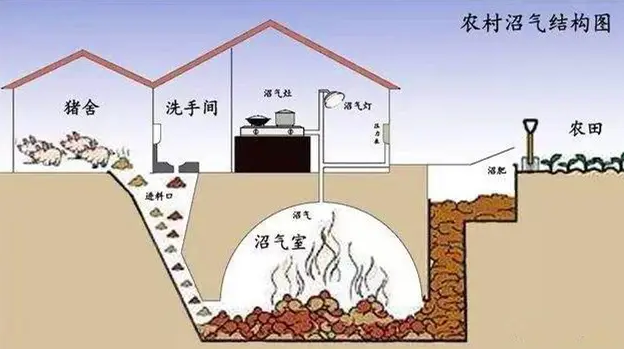

Biogas is a product of nature, a combustible gas produced by the combined action of multiple groups of microorganisms in anaerobic environments by organic matter (such as feces, straw, dead leaves, etc.). It is a clean and green energy source.

The main components of biogas are 55% -70% methane, 25-40% carbon dioxide, and a small amount of hydrogen sulfide, nitrogen, hydrogen, carbon monoxide, oxygen, etc. Since it was first discovered in swamps, it is called biogas

Biogas is just as dangerous as natural gas, and improper use can cause explosions, poisoning, and casualties. So when using biogas, one must not leave people and pay attention to air circulation. If there are children at home, after using biogas, in addition to turning off the stove switch, the main switch of the upper control should also be turned off to prevent children from playing and igniting biogas at home, causing fire or suffocation accidents.

Natural gas is a non renewable energy source, while biogas is a green renewable energy source. The fermented biogas residue can be used as fertilizer, forming a cycle that is inexhaustible.

At the same time, the development of biogas can treat some human and livestock manure, straw, sewage, etc., and to some extent, it can also improve the living environment and quality of life.

Three stages of biogas fermentation

One is the liquefaction stage. In biogas fermentation, the first step is for the fermentative bacterial community to utilize extracellular enzymes secreted by it, such as cellulase, amylase, protease, and lipase, to perform in vitro enzymatic hydrolysis of organic matter. This involves breaking down large molecule organic matter such as poultry manure, crop straw, and wastewater from soybean processing into water-soluble small molecule compounds such as monosaccharides, amino acids, glycerol, and fats.

One is the liquefaction stage. In biogas fermentation, the first step is for the fermentative bacterial community to utilize extracellular enzymes secreted by it, such as cellulase, amylase, protease, and lipase, to perform in vitro enzymatic hydrolysis of organic matter. This involves breaking down large molecule organic matter such as poultry manure, crop straw, and wastewater from soybean processing into water-soluble small molecule compounds such as monosaccharides, amino acids, glycerol, and fats.

The second stage is the acid production stage. The combined action of three bacterial populations involves the absorption of small molecule compounds produced during the liquefaction stage by fermentative bacteria into the cells, which are then decomposed into acetic acid, butyric acid, hydrogen, and carbon dioxide. Then, the hydrogen producing bacteria convert the propionic acid and butyric acid produced by fermentative bacteria into acetic acid, hydrogen, and carbon dioxide that can be utilized by methanogens.

The third stage is methane production. The methane producing bacterial community can be divided into two major groups: hydrogen consuming methane producing bacteria and acetic acid methane producing bacteria. There are over 70 types of methane producing bacteria that utilize the decomposition and transformation of small molecule compounds such as formic acid, acetic acid, hydrogen, and carbon dioxide from the three non methane producing bacterial communities mentioned above to generate methane.

The growth of methane producing bacteria is very slow. For example, when methane octacoccus grows on acetic acid, its growth time is 1-2 days, and the doubling time of methane mycelium is 4-9 days; Moreover, it is strictly anaerobic and highly sensitive to oxygen and oxidants, making it impossible to survive in the presence of air; They require neutral to alkaline and suitable temperature environmental conditions. So the biogas digester needs to be sealed to prevent the biogas from escaping or oxygen from entering, and to control the temperature and pH well.